Our Buzz, Squeak and Rattle (BSR) Testing Services help you gain the competitive edge you need to succeed in the market.

What is Buzz, Squeak and Rattle (BSR) Testing?

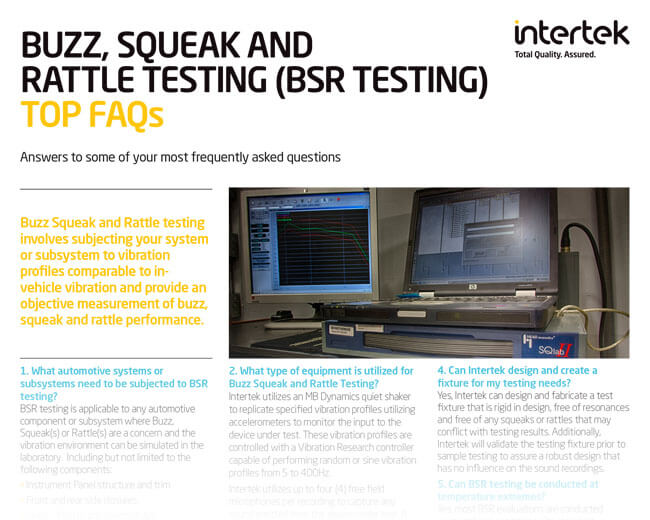

Buzz, Squeak and Rattle (BSR) testing uses real life data to recreate real-world road profiles helping to identify, isolate, and remove unwanted sounds for components within automobiles, such as buzzing, squeaking, or rattling.

BSR Testing Benefits

Buzz, Squeak and Rattle (BSR) Testing

Buzz, Squeak and Rattle (BSR) testing is a type of evaluation performed on vehicles and other mechanical systems to identify and assess any unwanted noises, vibrations, or rattles that may occur during normal use. The benefits of conducting BSR testing include:

- Improved customer satisfaction: BSR testing helps identify and resolve any potential sources of unwanted noise, vibration, or rattle, improving the overall customer experience and satisfaction with the vehicle or system.

- Increased reliability: By identifying and resolving potential sources of noise, vibration, or rattle, BSR testing helps improve the reliability of the vehicle or system, reducing the risk of component failure and the need for repairs.

- Improved product quality: BSR testing helps identify potential quality issues early in the development process, allowing manufacturers to make necessary design modifications to improve the quality of the final product.

- Reduced warranty costs: By identifying and resolving potential sources of noise, vibration, or rattle, BSR testing helps reduce the number of warranty claims and the associated costs.

- Competitive advantage: By conducting BSR testing and resolving any potential issues, manufacturers can demonstrate their commitment to quality and reliability, giving them a competitive advantage in the market.

Overall, BSR testing provides a number of benefits that help improve the quality, reliability, and customer satisfaction of vehicles and other mechanical systems, while also reducing warranty costs and giving manufacturers a competitive advantage in the market.

Intertek's BSR Testing Solutions

Utilizing Intertek’s low-noise vibration system to evaluate your product's Buzz, Squeak, and Rattle performance can help your product to stand out. We offer BSR testing with an MB Dynamics Energizer low-noise vibration system that can test instrument panels and consoles, cockpits, seats, seat belt retractors, HVAC assemblies, vent registers, airbag modules, clusters, steering column assemblies, radios, and audio equipment.

In this on-demand webinar, Intertek’s Rich Byczek explores the science and application of Buzz, Squeak, and Rattle (BSR) Testing in Automotive Development

Intertek's BSR Testing Capabilities/Equipment:

MB Dynamics Energizer Low-noise Vibration System Specifications

- System noise less than 1.5 sones

- Background Sound Levels less than 26 dBA

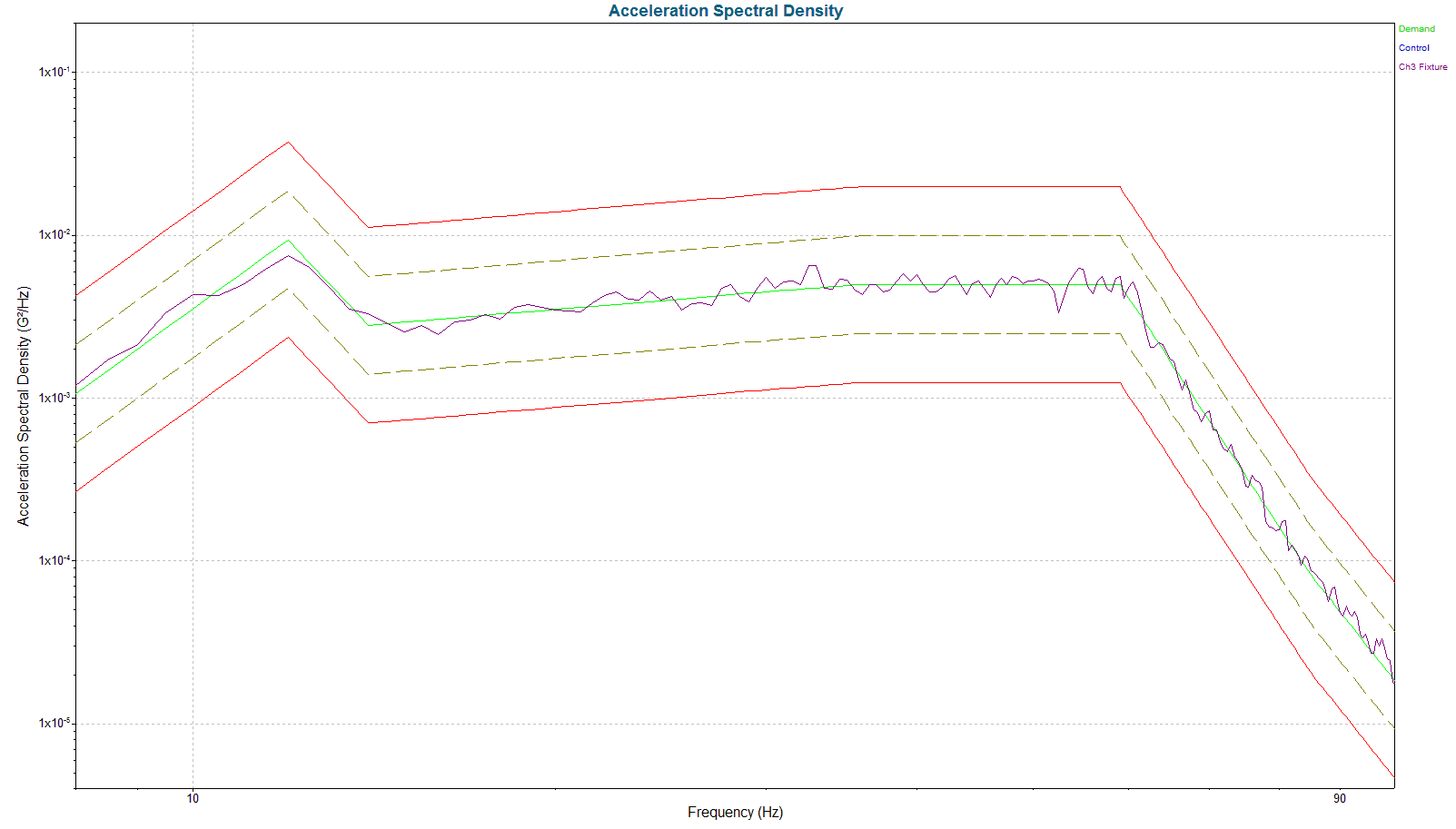

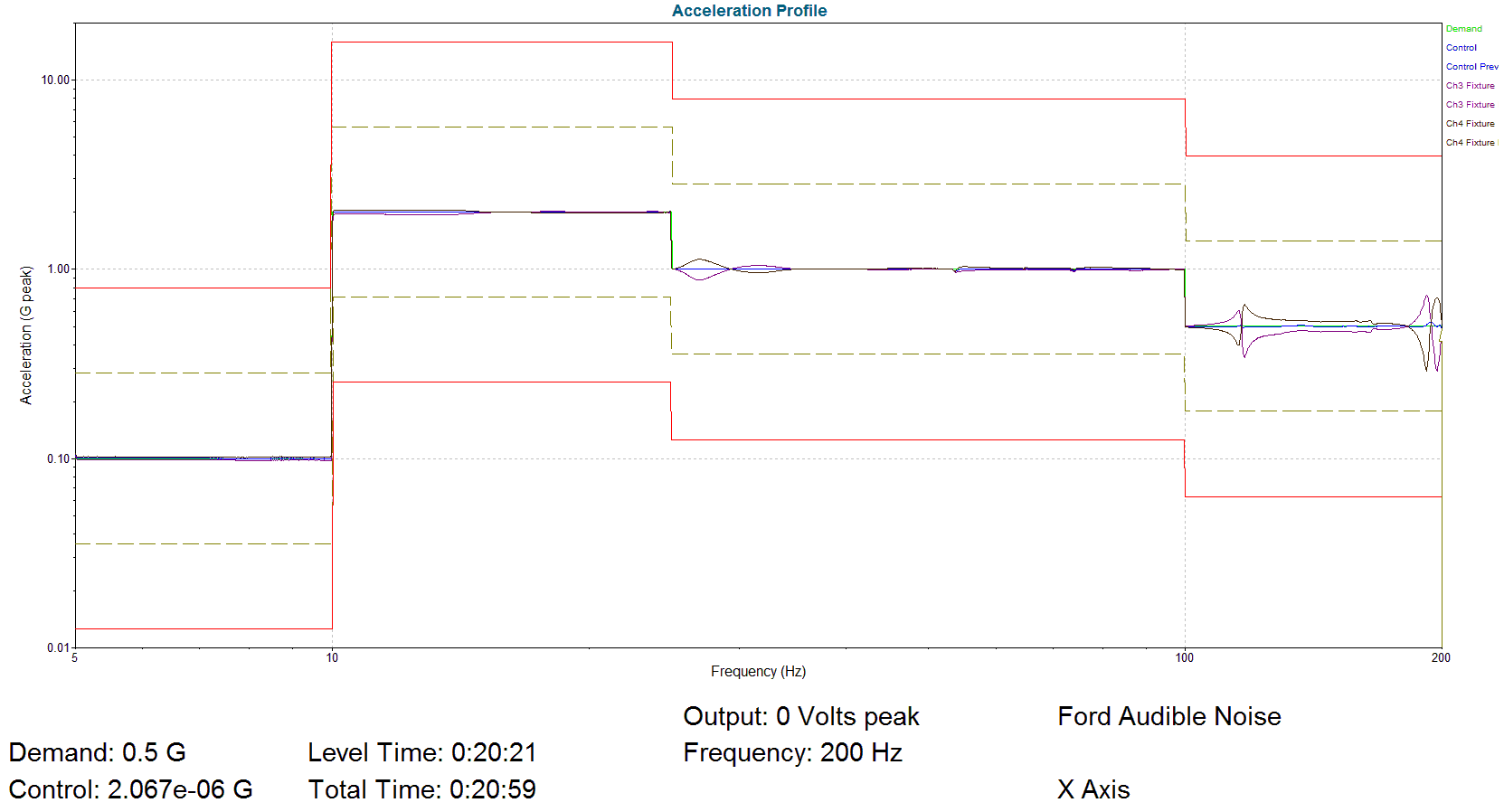

- Random and Sine vibration profiles

- Custom profiles utilizing actual Road Load Data Acquisition also available

- 6'x3' payload area: can accommodate most vehicle subsystems

- Capacity to 300 pounds

- Flexible fixturing allows single sample mounting to be used for 3 axes of vibration.

Measurement Capabilities

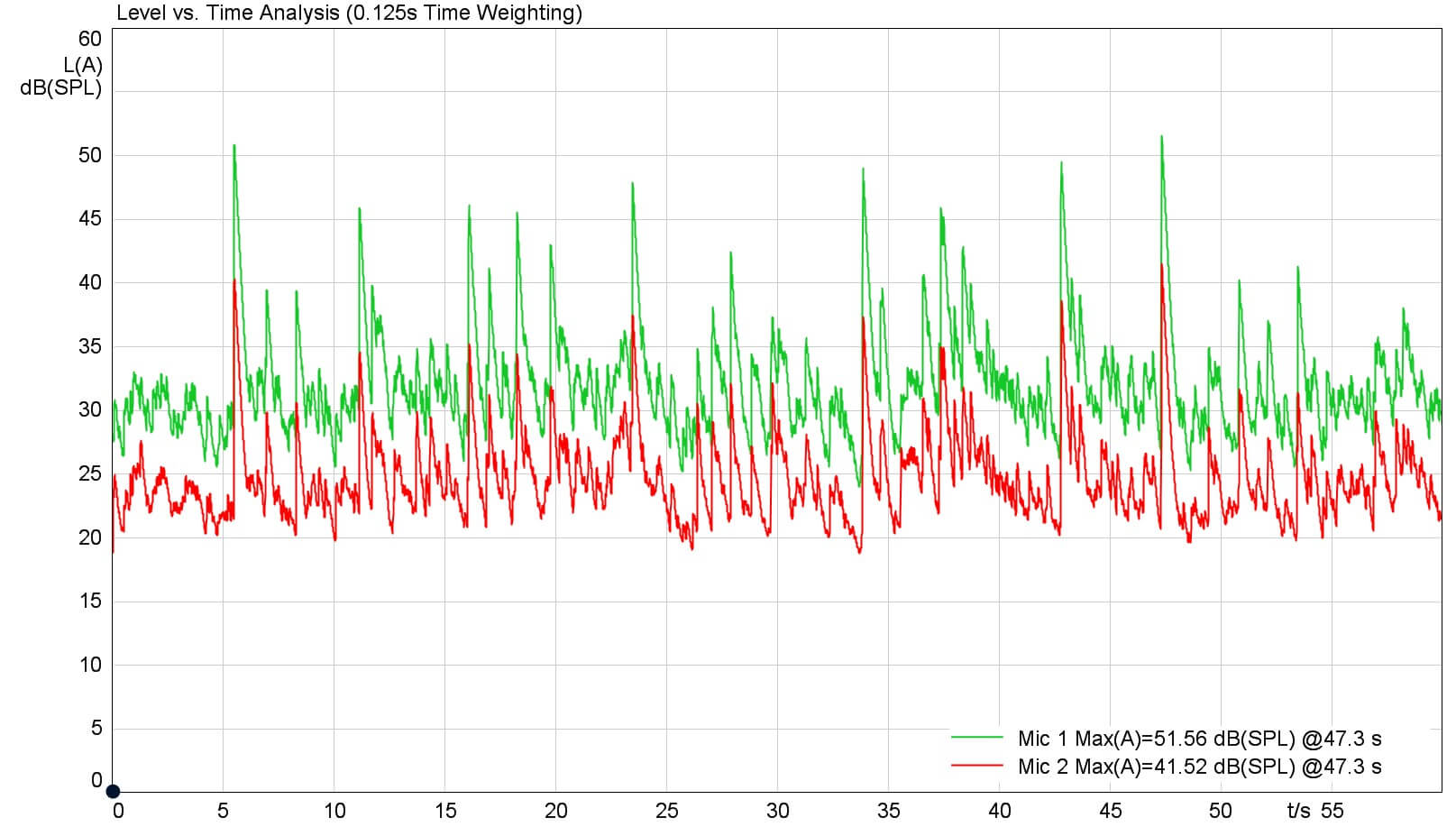

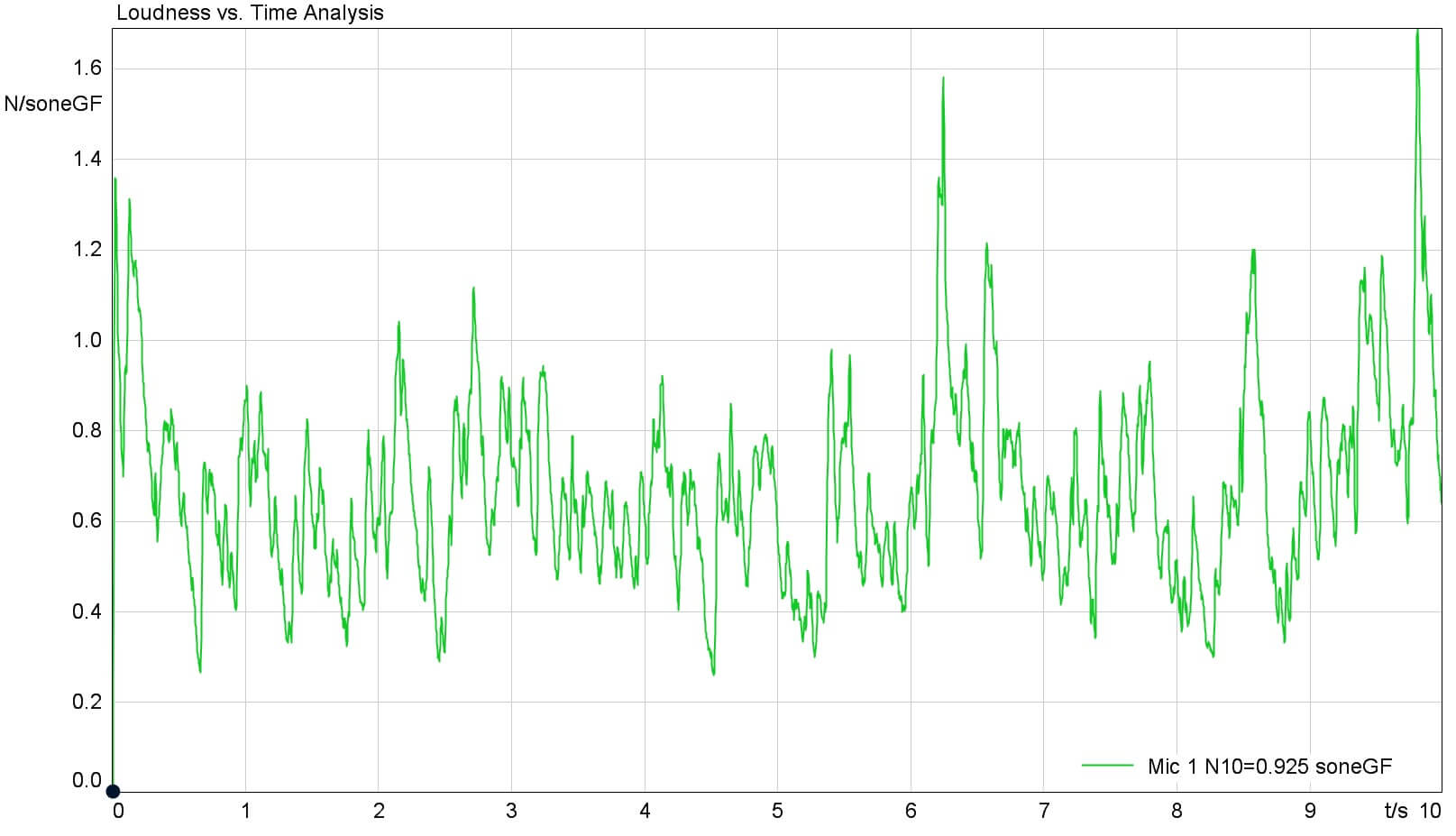

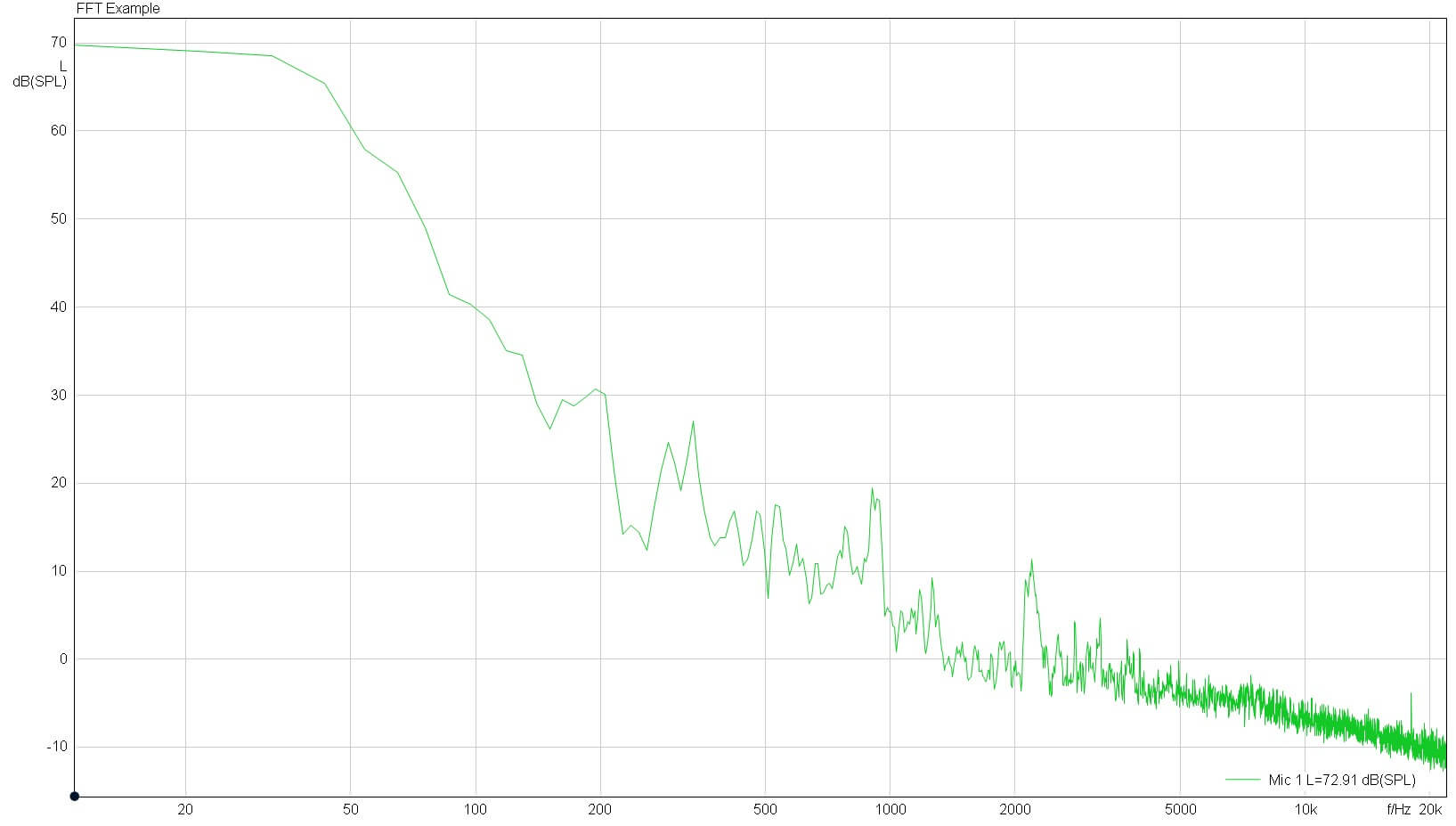

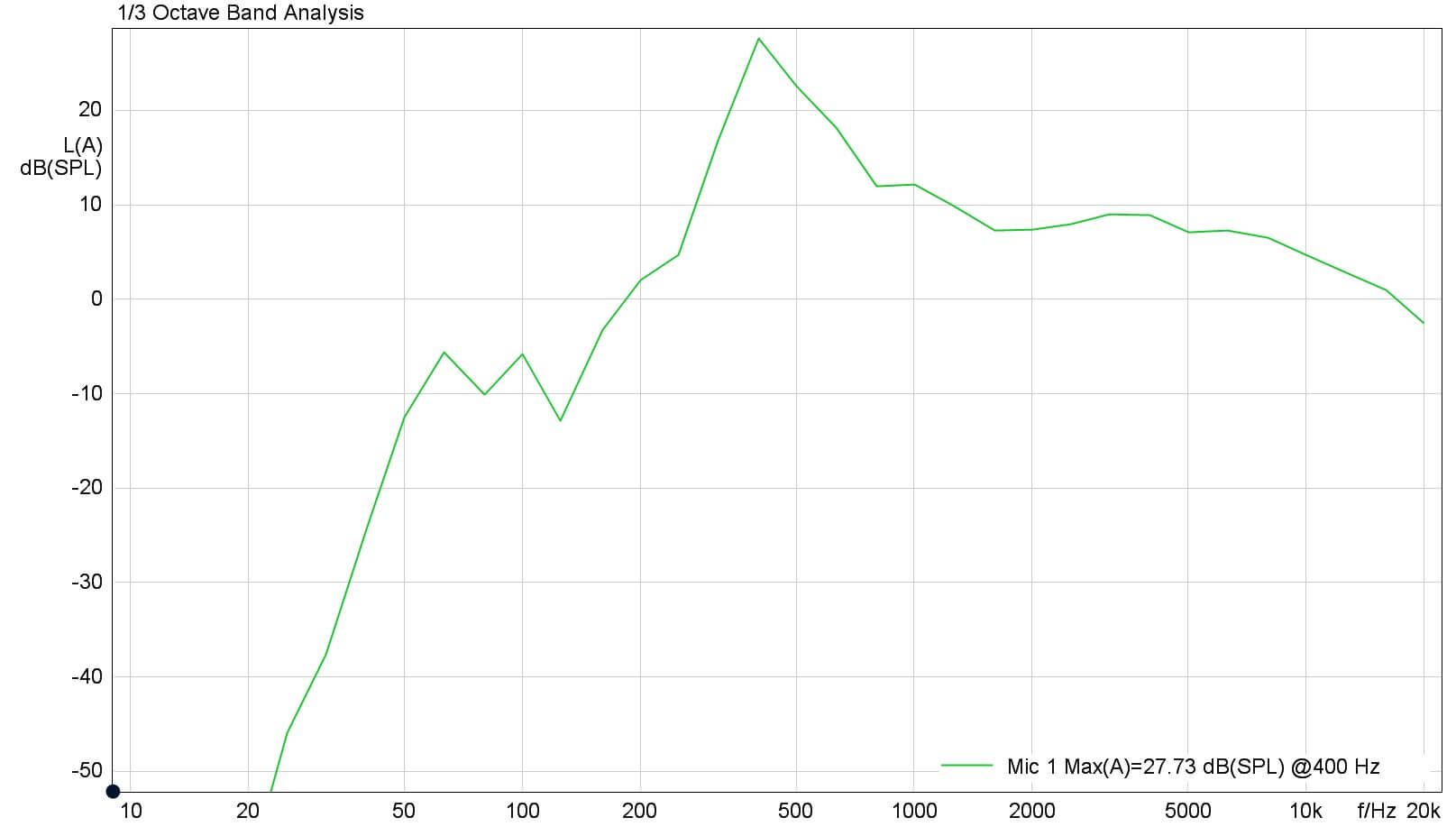

- Multiple Sound Measurement Software and hardware equipment up to 4 Microphone inputs:

- Head Acoustics Data Acquisition and Signal Processing

- Sound Pressure Level (SPL) Flat Response, A-weighted, custom filtered, post-processing of raw data

- Frequency Response: 1/3, 1/24 octave Spectrum Analysis

- Instationary Zwicker Loudness (Sones) Per ISO 532

- Level vs. Time Analysis

Test Standards for BSR (Buzz, Squeak and Rattle)

- General Motors: GMW 7293, GMW14011, etc.

- Ford Motor Company: CETP 15.01-L-402, CETP 12.00-L-405, CETP 00.00-E-412, etc.

- Custom specification requiring low background noise levels

BSR Test Examples:

Knowledge Center

Buzz, Squeak, and Rattle (BSR) Testing in Automotive Development Webinar

Master FMVSS 108 Compliance – Download the Expert Guide

Automotive Functional Safety & Cyber Security FAQs

Development of Driveline Electrification Technologies White Paper

Understanding Failure Analysis and Answering your Frequently Asked Questions

The Top-7 FAQs of Autonomous Vehicles Testing

The Top-10 FAQs of Advanced Composites Testing

The Top-10 FAQs of Automotive Interior Testing

Accelerated Stress Testing to Manage Disruptive Market Changes Webinar

Transitioning to Structural Composites to Meet CAFE Standards

Automotive Interiors Testing White Paper

Resources

Global Research & Certification

SatelliteTM Client Test Program

Engineering and Technical Staffing

SupplyTek - gain the confidence to go to market faster

Protek - safeguard people, systems and processes, facilities, materials and surfaces, and products