Protein aggregation analysis and characterization to assess the extent of protein degradation, stability and formation of aggregates in solution

Protein aggregation analysis and characterisation is key to successful biopharmaceutical development and manufacturing. Protein aggregates can form at any stage of the development or manufacturing process, including bioprocessing, purification, formulation and packaging and also during shipping or storage. During formulation development, for example, an understanding of protein stability and aggregation analysis helps drive an understanding of the effects that excipients have on the stability of the protein, enabling rational development of the drug substance and drug product.

What Are Protein Aggregates?

Protein aggregates can be considered an impurity, or a molecular variant, resulting from changes that take place over time and/or by the action of physical factors. Factors affecting protein aggregation include light, temperature, pH, water, shear-forces, during mixing, or by reaction with an excipient in the formulation, concentration of buffers or interaction with the container/closure system (e.g. stainless steel particles, rubber particles from elastomer seals or glass delamination). Aggregates include reversible non-covalent and irreversible covalent bonded species, dimers, oligomers and higher multiples, of the desired protein product and can be present as small soluble particles ranging in size from a few nm to large sub-visible or even visible particles up to microns. This wide range size can present challenges in analysing protein aggregates as no single technique is able to cover this size range, therefore a combination of several techniques is necessary.

Aggregation of a protein therapeutic can have serious implications for patient safety, biologic product stability, potency, biological activity, quality, and efficacy. As aggregation has been reported to lead to adverse immune reactions in patients, it is important to mitigate health risks during drug development through a comprehensive understanding of your biomolecule’s propensity to aggregate and characterisation of the aggregation state.

Protein Aggregation Detection Methods

Our experts apply a range of protein aggregation analysis techniques to detect and quantify aggregates in solution, supporting formulation development, quality control, stability studies, comparability, release testing and characterization of protein aggregates throughout product development. We can conduct aggregation analysis in accordance with the requirements of the ICH Q6B guideline, offering studies to either Good Laboratory Practice (GLP) or Good Manufacturing Practice (GMP) using techniques such as differential scanning calorimetry (DSC), analytical ultracentrifugation (AUC), and dynamic light scattering protein aggregation studies (DLS) and other light scattering techniques (SEC-MALS), which allow the study of non-covalent structural aspects of a protein and also study of aggregates or oligomer formation in solution.

Analytical ultracentrifugation data analysis allows the assessment of the homogeneity of proteins / peptide solutions and to qualitatively assess the molecular weight and presence of aggregates over a broad range of molecular weights ranging from a few kDa to MDaltons. AUC, therefore, allows a unique analysis of multiple species in the same sample, while most of the other methods used for aggregation analysis are limited by either the size range or the resolution between different oligomers.

For submicron aggregates, size-exclusion chromatography (SEC) is routinely used to detect and quantify irreversible aggregates from oligomers through to ultra-high order aggregates. This technique is used to establish the molecular weight of observed aggregates and is typically coupled with multi-angle static light scattering (SEC–MALS).

DLS protein aggregation studies allow the generation of data (R&D, GLP or cGMP) allowing the measurement of particulate size distribution of proteins in solution, particle size analysis (0.6nm to 6 microns) and zeta potential measurement / electrostatic aggregation. DLS can also be applied to measure and understand nanoparticles in healthcare products, including nanoliposome encapsulation.

Protein Aggregation Analytical Techniques:

- Analytical ultracentrifugation (AUC)

- Size exclusion chromatography (SEC, SEC-MALS)

- Dynamic light scattering (DLS)

- Light obscuration

- Zeta potential

- Capillary electrophoresis CE (CZE, MECC, Gel CE, cIEF/iCIEF)

- Gel electrophoresis (Native, SDS-PAGE, IEF)

- Electron microscopy (TEM and SEM)

- Circular dichroism (CD)

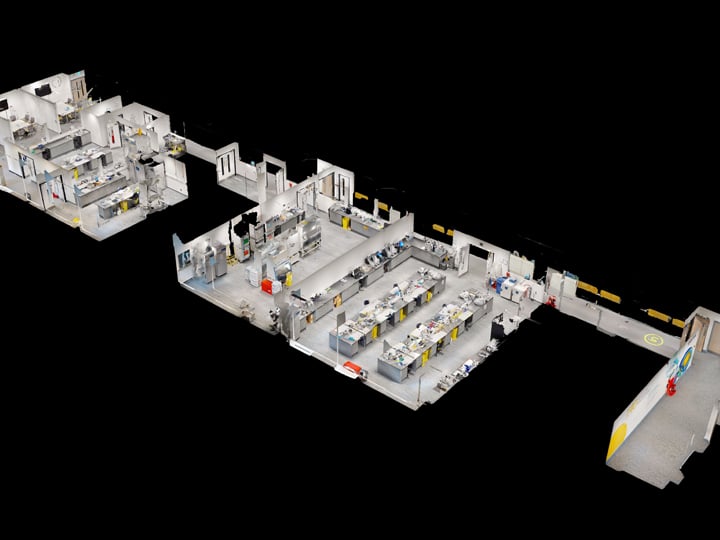

Through our unique level of lab services, extensive expertise, and proven experience, we can expedite your protein aggregate analysis and characterisation needs to meet your formulation development, quality control, submission, comparability, stability or batch release testing requirements. Bringing quality and safety to life, we offer Total Quality Assurance expertise to help you to meet and exceed quality, safety and regulatory standards concerning aggregation. As a key part of our leading biophysical characterisation portfolio for biologics, we deliver efficient and detailed information to drive insight for your biopharmaceutical development programs.

Pharmaceutical News & Events

- PRESS RELEASE! Intertek partners with CrystecPharma to advance formulation science and accelerate development for dry powder inhalers

- NEW! Blog: Optimising Quality in Pharma Supply Chains

- Determination of Particles in Pharmaceuticals - Article

- Discover our Audit Live Tool for direct access to our scheduled audits

- Extractables/Leachables Lab Tour - Request access

- Medical Device Extractables & Leachables Studies

- Glycosylation Analytical Approaches for Antibody Therapeutics

- Rapid Determination of Low/Trace Level Benzene in Pharmaceutical Excipients and Finished Products

COVID-19 VACCINE OR THERAPEUTIC TESTING & DEVELOPMENT SUPPORT

IMMEDIATE QUESTION? Ask our experts now

FACTSHEET: COVID-19 Vaccine or Therapeutic Testing & Development Outsourcing

ARTICLE: Repurposing Vaccines for Intranasal Development

WEBINAR: Quality Control Strategy for Vaccine Development

WEBINAR: Repurposing Drugs for Inhaled Delivery

eBOOK: Contingency Outsourcing Solutions